iSupervisor TAS+

- Terminal automation systems providing automated tanker loading are now a key requirement for both the large storage terminal and the smaller distribution depot alike.

- Automated tanker loading systems afford the user greater control of meter deliveries, accurate reporting of meter movements and increased safety during the loading process.

- The iSupervisor TAS platform is an automation system that is modular in design which acts as a layer between site instrumentation and the user and can be provided as a complete terminal automation system (TAS) for the main storage distribution terminal. However, the system is infinitely flexible and can be scaled down and provided as a basic system for small depot operators.

- In every case the open connectivity of the system provides the user with access and control locally at the storage facility and remotely from any location through a web interface.

- EA Projects offer a range of solutions for terminal automation incorporating every requirement of the modern loading facility such as injection of performance additives and rack blending of bio-ethanol and bio-diesel.

- Tailored modules are available for management of petroleum, fuel oils, liquid natural gas (LNG), liquid petroleum gas (LPG), chemical and food products.

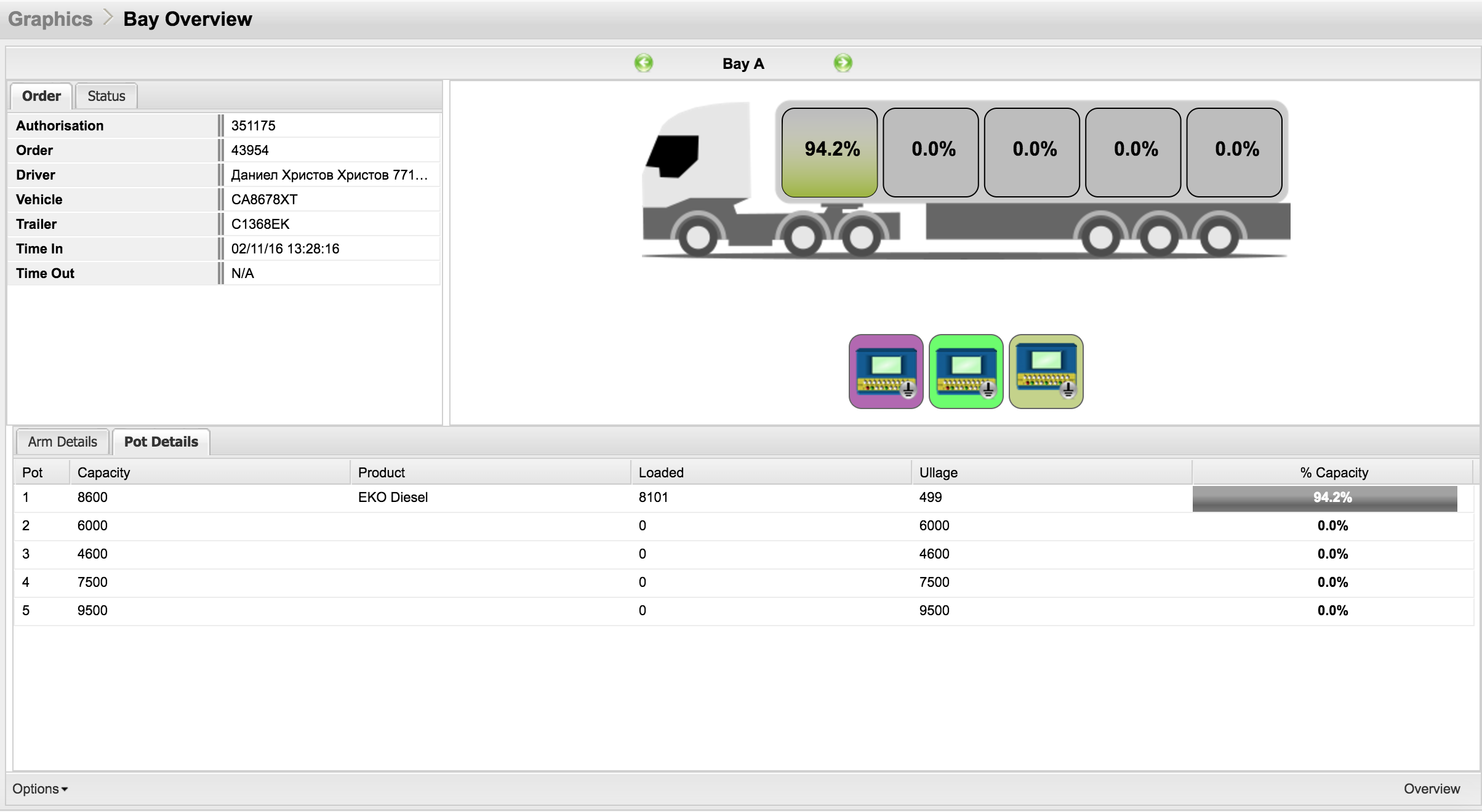

- The system provides full control of the complete tanker loading process from order entry through to Bill of Lading production and head office reporting. Multi-tiered graphical screens provide dynamic data received from site instrumentation and an integrated event log records all system activity and site operations.There are a number of detailed reports which can be exported directly in a variable number of formats or alternatively the system can be fully integrated with third party enterprise resource or accounting systems.

- The system is installed at a large number of locations globally and is fully configurable in a multitude of languages including English, Spanish, Chinese and French.